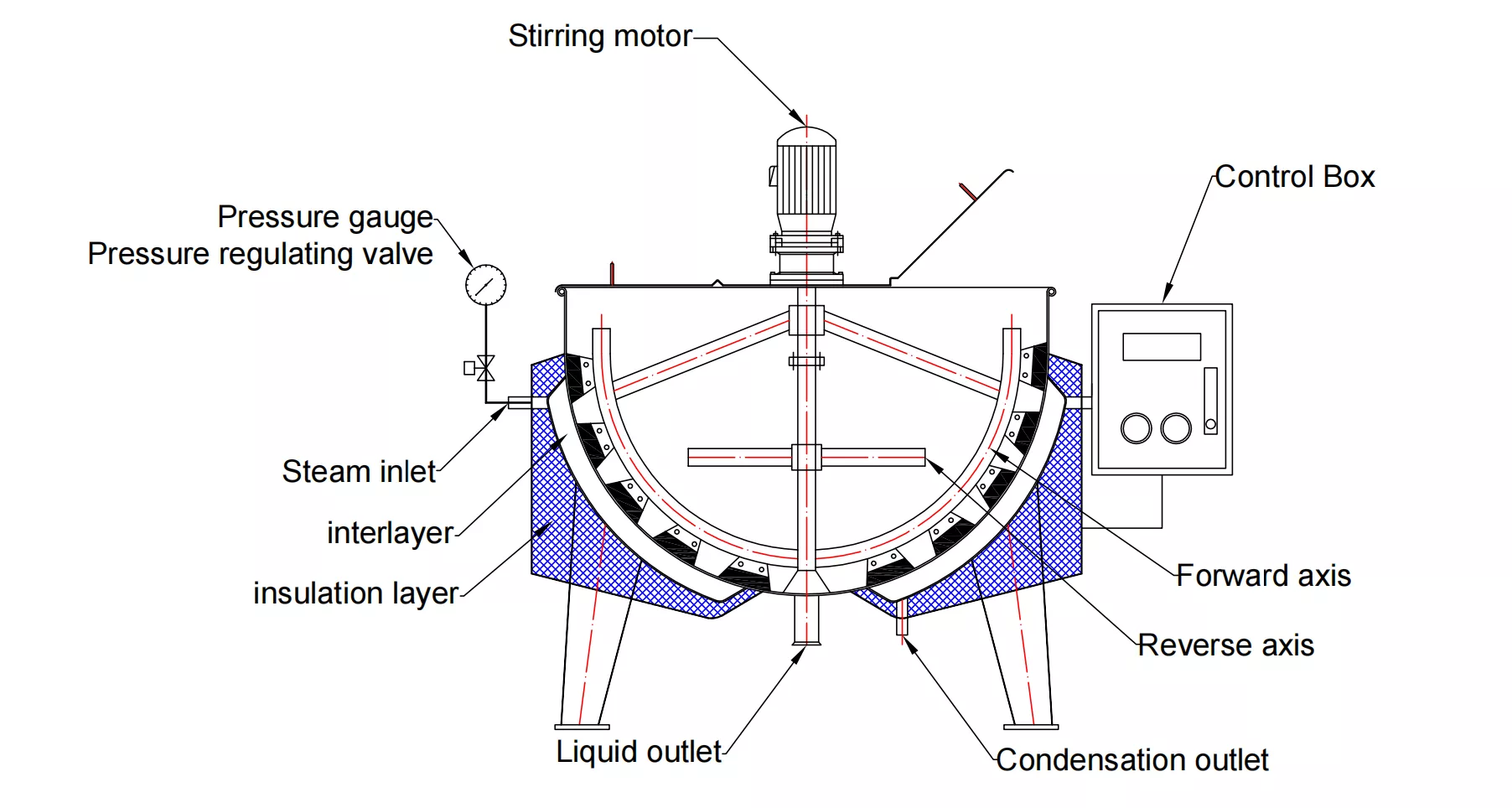

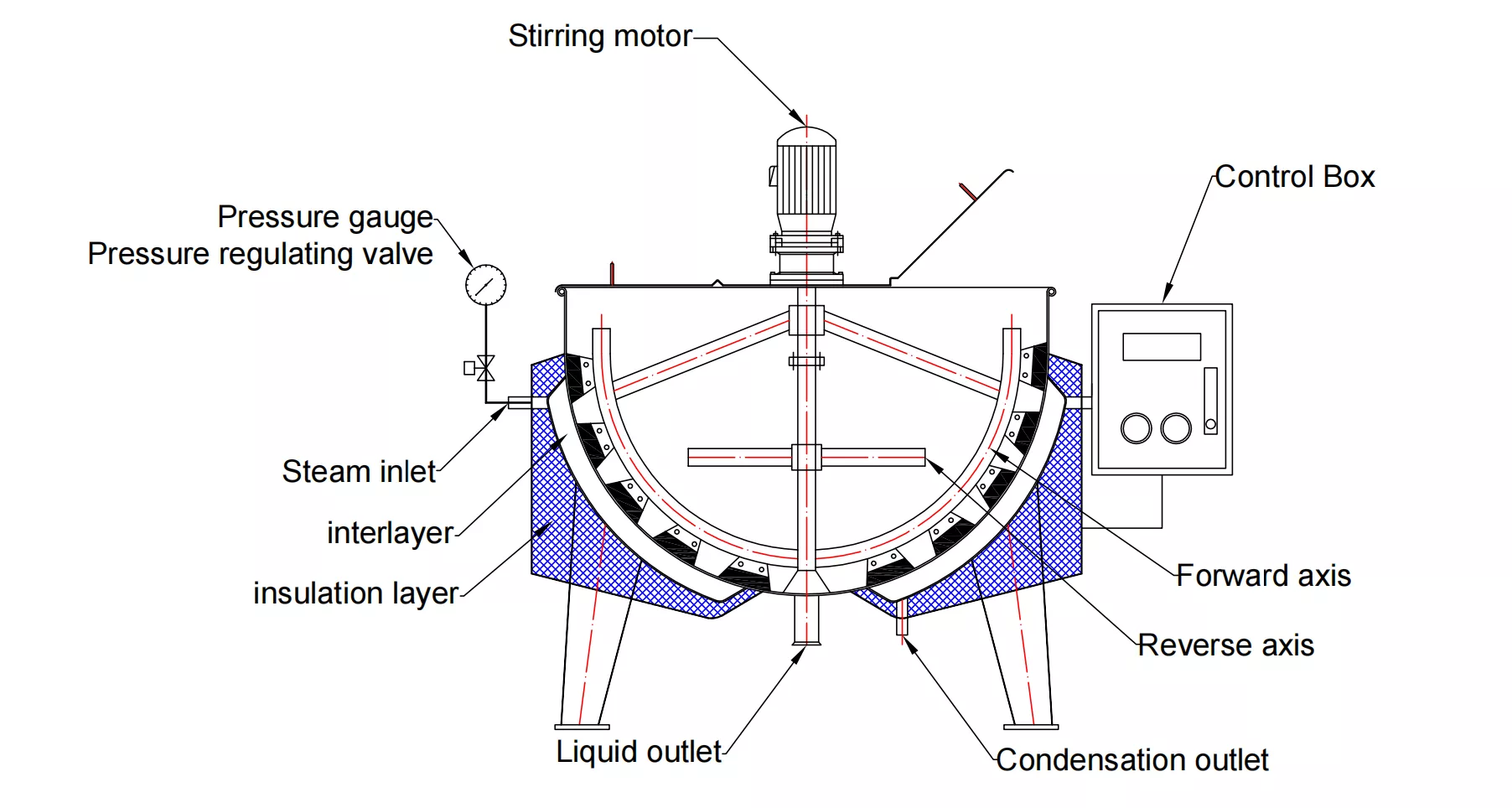

Tomato paste cooking and mixing jacketed kettle

Applications

Vertical open mixing jacketed kettle is mainly used for small batches of cooked food processing and cooking in small factories, family workshops, etc., such as heating, stirring, cooking, and concentration of syrups, sauces, milk, chocolate and other materials. Hemispherical structure, heating and stirring evenly without dead ends.

Features

Made of food grade 304/316 material, jacket heat exchange heating with fast heating speed, electric heating/steam heating optional, open structure for easy observation and cleaning.

Applications

Model | Volume (L) | Diameter (mm) | Stirring power (Kw) | Heating method | Dimensions (mm) |

|

JYH-GLJ-50 | 50 | Φ600*450 | 0.75 | Z-steam/D-electric | 1250*950*1450 |

JYH-GLJ-100 | 100 | Φ700*500 | 1.5 | Z-steam/D-electric | 1350*1050*1450 |

JYH-GLJ-200 | 200 | Φ800*550 | 2.2 | Z-steam/D-electric | 1450*1150*1450 |

JYH-GLJ-300 | 300 | Φ900*600 | / | Z-steam/D-electric | 1550*1250*1550 |

JYH-GLJ-400 | 400 | Φ1000*650 | / | Z-steam/D-electric | 1650*1350*1650 |

JYH-GLJ-500 | 500 | Φ1100*700 | / | Z-steam/D-electric | 1750*1450*1650 |

JYH-GLJ-600 | 600 | Φ1200*750 | / | Z-steam/D-electric | 1850*1550*1650 |

ABOUT JINGYE MACHINERY

Jiangxi Jingye Machinery Technology Co., Ltd. is a machinery manufacturing enterprise integrating technology R&D. We specializes in the production and sales of food, beverage, pharmaceutical and chemical machinery, sanitary fluid pump valve accessories, etc., and provides process design, manufacturing and installation of food and beverage production lines, liquid milk production line sterilization equipment, etc. Commissioning, technical training and after-sales service to turnkey overall engineering services.

The main products include: autoclave, pressure cooker, mixing tanks, jacketed pots, reaction tank, plate heat exchanger, fermentation tanks, blending tanks, hot and cold cylinders, centrifugal pumps, beverage pumps, etc. Widely applicated in food and beverage category include production lines for sauces, bone broth, hummus, syrup, milk, juice, protein drinks (soy milk), fresh milk, tea drinks, eight-treasure porridge, etc.

The company takes product quality excellence as its core and service quality as its goal. While digesting and absorbing advanced domestic and foreign technologies, it combines its own advantages to continuously innovate and make progress. In line with the business purpose of "customer interests first, product quality first", we provide our customers with high-quality products and services.

+86 181 7003 7990

+86 181 7003 7990 aloe@cnjymachine.com

aloe@cnjymachine.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address

FREE CONSULTATION

FREE CONSULTATION