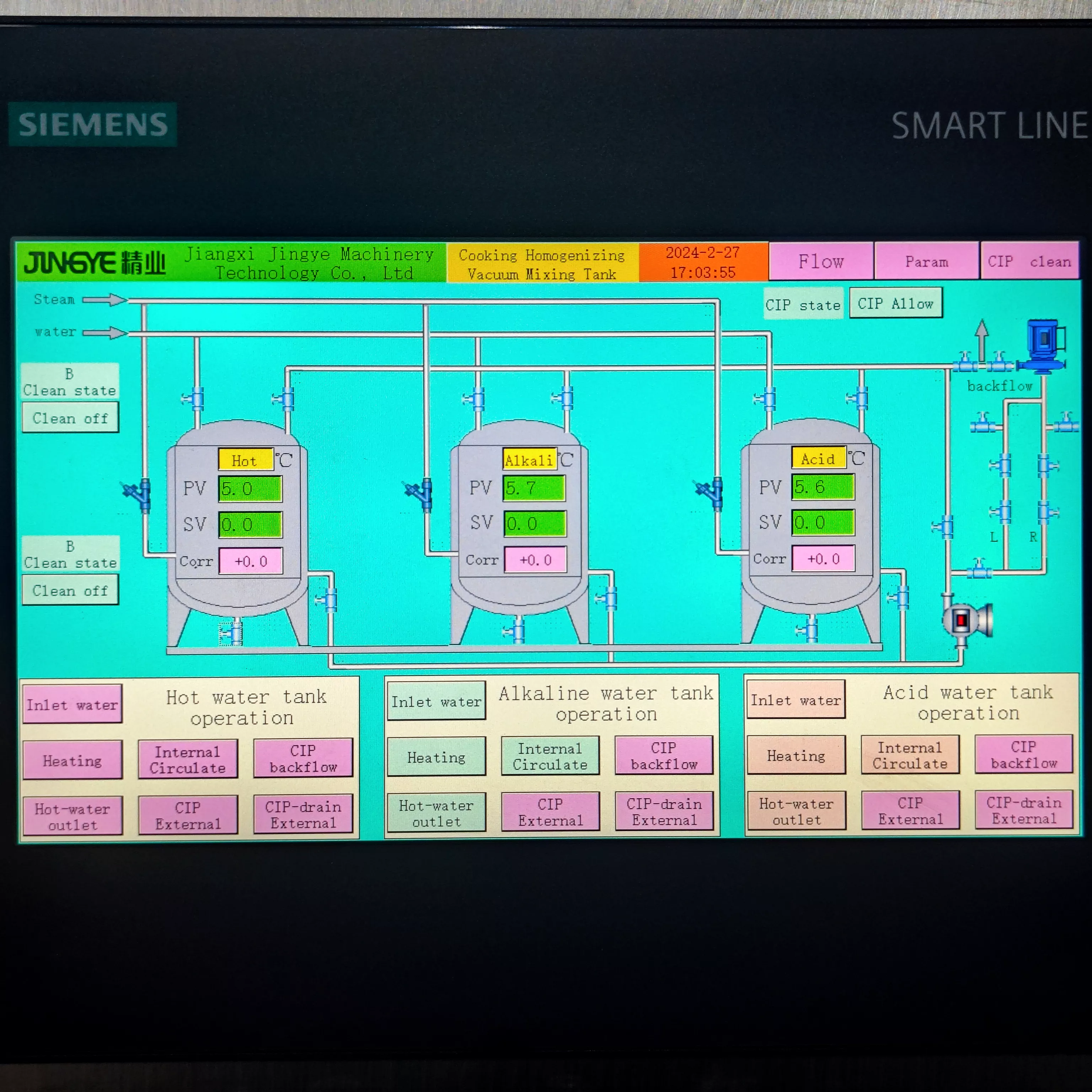

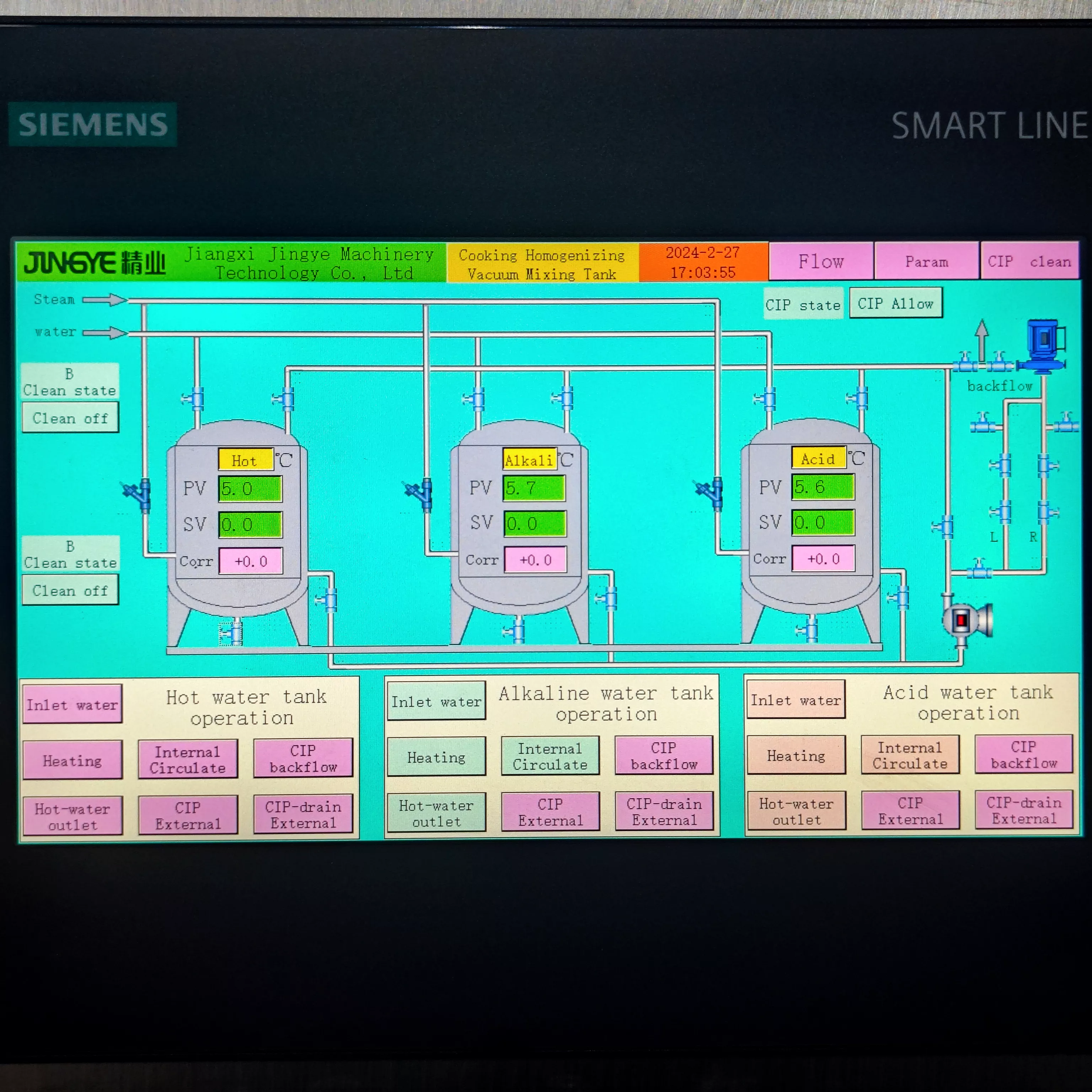

CIP cleaning system

This equipment is used to clean production lines such as various dairy products, sauces and cooked food processing plants. It consists of a hot water tank, an acid tank, an alkali tank and a circulation pump. No installation is required and the operation is simple. Using fully automatic operation, the cleaning process is automatically completed through a preset program without manual intervention, saving manpower and improving production efficiency. Through high-pressure water flow, alkaline or acidic cleaning liquid and high-temperature water, the inner surface of the equipment and piping system can be thoroughly cleaned to remove residual substances and microorganisms and ensure the hygiene of the equipment. Equipped with safety protection devices such as over-temperature protection, pressure protection, etc., to ensure the safety and reliability of the equipment during operation.

ABOUT JINGYE MACHINERY

Jiangxi Jingye Machinery Technology Co., Ltd. is a machinery manufacturing enterprise integrating technology R&D. We specializes in the production and sales of food, beverage, pharmaceutical and chemical machinery, sanitary fluid pump valve accessories, etc., and provides process design, manufacturing and installation of food and beverage production lines, liquid milk production line sterilization equipment, etc. Commissioning, technical training and after-sales service to turnkey overall engineering services.

The main products include: autoclave, pressure cooker, mixing tanks, jacketed pots, reaction tank, plate heat exchanger, fermentation tanks, blending tanks, hot and cold cylinders, centrifugal pumps, beverage pumps, etc. Widely applicated in food and beverage category include production lines for sauces, bone broth, hummus, syrup, milk, juice, protein drinks (soy milk), fresh milk, tea drinks, eight-treasure porridge, etc.

The company takes product quality excellence as its core and service quality as its goal. While digesting and absorbing advanced domestic and foreign technologies, it combines its own advantages to continuously innovate and make progress. In line with the business purpose of "customer interests first, product quality first", we provide our customers with high-quality products and services.

FREE CONSULTATION

FREE CONSULTATION

FREE CONSULTATION

FREE CONSULTATION