Water bath double tanks sterilization retort

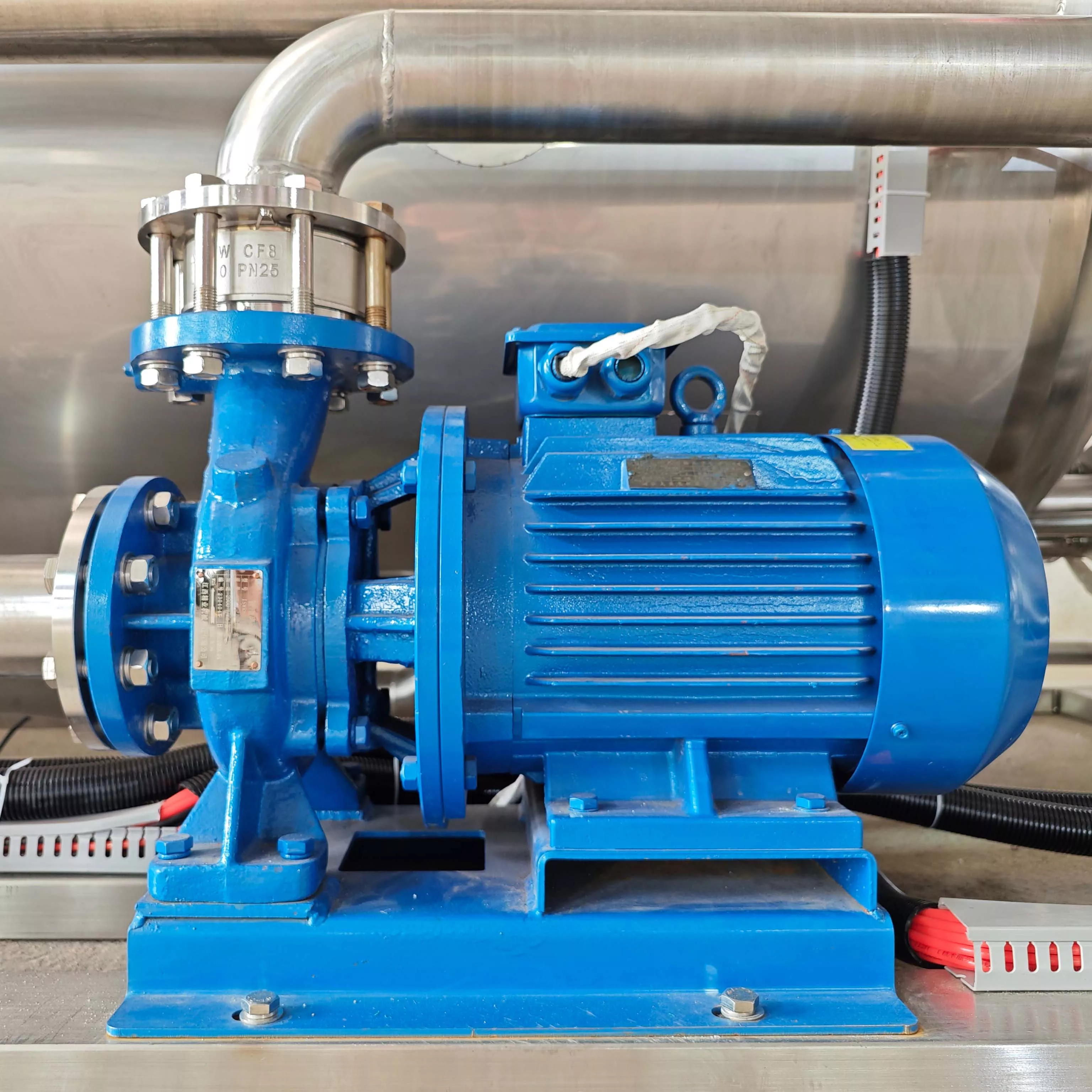

The pot body part : It is composed of a sterilization tank, a hot water tank, a pump and connecting pipes, and a PLC automatic control system.

Control part : It adopts 10-inch PLC + touch screen programming control to realize one-button start sterilization, intelligent control of sterilization temperature and pressure, and analog sensors and automatic valve control are available for all time periods. A variety of sterilization processes can be pre-saved to save manpower and cumbersome operation procedures.

Sterilization method : Water bath sterilization, firstly heating the water in the hot water tank to reach the temperature required for sterilization (except for multi-stage sterilization), thereby shortening the operation time and improving work efficiency. The water in the tank is constantly switched up, down, left and right to circulate and sterilize evenly, with uniform temperature and no dead corners.

Heating method : Electric/steam heating, which can be matched according to on-site conditions

+86 181 7003 7990

+86 181 7003 7990 aloe@cnjymachine.com

aloe@cnjymachine.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address

FREE CONSULTATION

FREE CONSULTATION