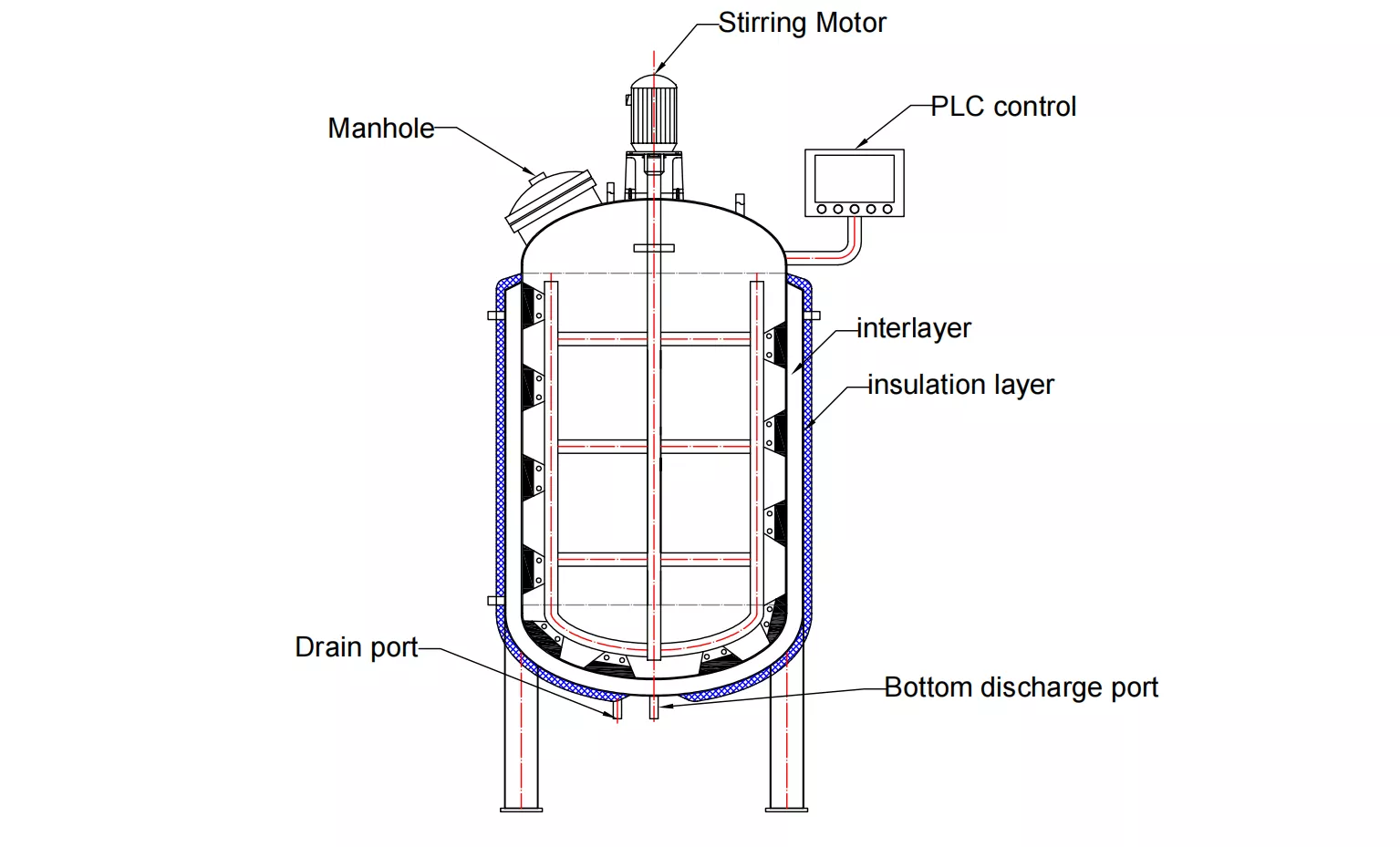

Bone Broth Cooling Mixing Tank

Model | Volume (L) | Diameter (mm) | Heating power (Kw) | Heating method | Dimensions (mm) |

JYH-JCJE-500 | 500 | Φ900*800 | 2.2 | Z-steam/D-electric | 1350*1150*2250 |

JYH-JCJE-1000 | 1000 | Φ1100*1000 | / | Z-steam/D-electric | 1550*1350*2450 |

JYH-JCJE-2000 | 2000 | Φ1300*1500 | 3 | Z-steam | 1850*1650*2850 |

JYH-JCJE-3000 | 3000 | Φ1600*1500 | / | Z-steam | 2150*1950*2950 |

JYH-JCJE-5000 | 5000 | Φ1800*2000 | / | Z-steam | 2350*2150*3450 |

Jiangxi Jingye Machinery Technology Co., Ltd. is a machinery manufacturing enterprise integrating technology R&D. We specializes in the production and sales of food, beverage, pharmaceutical and chemical machinery, sanitary fluid pump valve accessories, etc., and provides process design, manufacturing and installation of food and beverage production lines, liquid milk production line sterilization equipment, etc. Commissioning, technical training and after-sales service to turnkey overall engineering services.

The main products include: autoclave, pressure cooker, mixing tanks, jacketed pots, reaction tank, plate heat exchanger, fermentation tanks, blending tanks, hot and cold cylinders, centrifugal pumps, beverage pumps, etc. Widely applicated in food and beverage category include production lines for sauces, bone broth, hummus, syrup, milk, juice, protein drinks (soy milk), fresh milk, tea drinks, eight-treasure porridge, etc.

FREE CONSULTATION

FREE CONSULTATION

FREE CONSULTATION

FREE CONSULTATION